Even for those of us who consider ourselves to be pretty handy within the home improvement world, the thought of pouring self leveling concrete IN OUR HOUSE is moderately terrifying. O.K., completely terrifying. Don't worry. You can do this.

The VCT floor I laid, on top of the cement I poured, over the self installed heated floors.

First things first. I ate a whole can of Pringles today. They were Salt & Vinegar and now my tongue feels like I ate a ball of sandpaper. That might not seem pertinent to the task at hand - and it isn't.

When I redid my kitchen a decade ago I really wanted to address my cold floors. So I ripped out all of my ceramic tile and laid down heated floor mats. That wasn't scary at all. Pouring buckets of self leveling concrete over them WAS.

The cement floor would encase the heating elements, allow them to radiate heat still, plus provide a level smooth surface for tiles. That was my reason for pouring cement all over my floors and working myself into a panic.

Whatever your reason, you don't need to be afraid. I say that because I was afraid. Really afraid. Letter from the tax department afraid. You don't need to be.

Table of Contents

Using Self leveling concrete

Self levelling concrete is cement based like traditional concrete, but it flows much easier and sets up more quickly due to polymers added to it. It's used to create a smooth, level surface for laying carpet, ceramic tiles or other floor coverings on.

For use almost exclusively on interior flooring.

Self leveling cement (concrete) can be poured up to a 1 inch thickness.

Materials

- Self leveling concrete*

- Leveling primer**

- a cement mixing paddle

- a strong drill (rent an industrial one)

- 5 gallon bucket

- trowel

- filler (like Durabond 90)

* It may also be called self leveling concrete, leveling compound, self leveling floor resurfacer or self leveling underlayment. Make sure you get REGULAR instead of QUICK DRYING. Regular will give you more time to work and spread out the material before it starts to set.

** Primer is needed when you're pouring concrete onto a porous surface like an existing concrete floor. It isn't needed when pouring onto old tile.

Method

PREP WORK

- Scrape up any loose debris or old tiles from the floor.

- Fill any cracks or holes with Durabond 90 and create a dam to prevent the runny concrete from seeping anywhere you don't want it to go.

- Vacuum so you have a clean surface.

- Gather your materials.

The brand of resurfacer doesn't matter so much as the type. There are 2 types. Quick drying and regular. You want regular.

POURING

- Add the required amount of water to the bucket FIRST. (the bag will tell you how much water to compound mix to use)

- Add ¼ - ⅓ of the powdered compound. Mix with water using the drill. Continue mixing in the remainder of the bag bit by bit until it's all incorporated. Mix for prescribed amount of time as detailed on the bag.

For one bucket of concrete a strong cordless drill will do the job, but if you have any more than 1 bucket to do you're in trouble. The battery will die after 1 or 2 buckets. Then you'll go for your corded drill, which will burn out and will get thrown in the garbage.

Save your anger, your sanity and your relationship and RENT AN INDUSTRIAL DRILL. After the first day I rented a strong drill for $20 for half a day.

- Pour your leveling compound where you want it.

- Trowel it. Using a trowel push and pull the mixture where it needs to go. Push it into corners and pull it towards you. Excuse my hair. It appears I was having a Paul Weller moment.

- Clean up your drips.

- Wait 24 hours to walk on it.

- Wait 3 days to place furniture back.

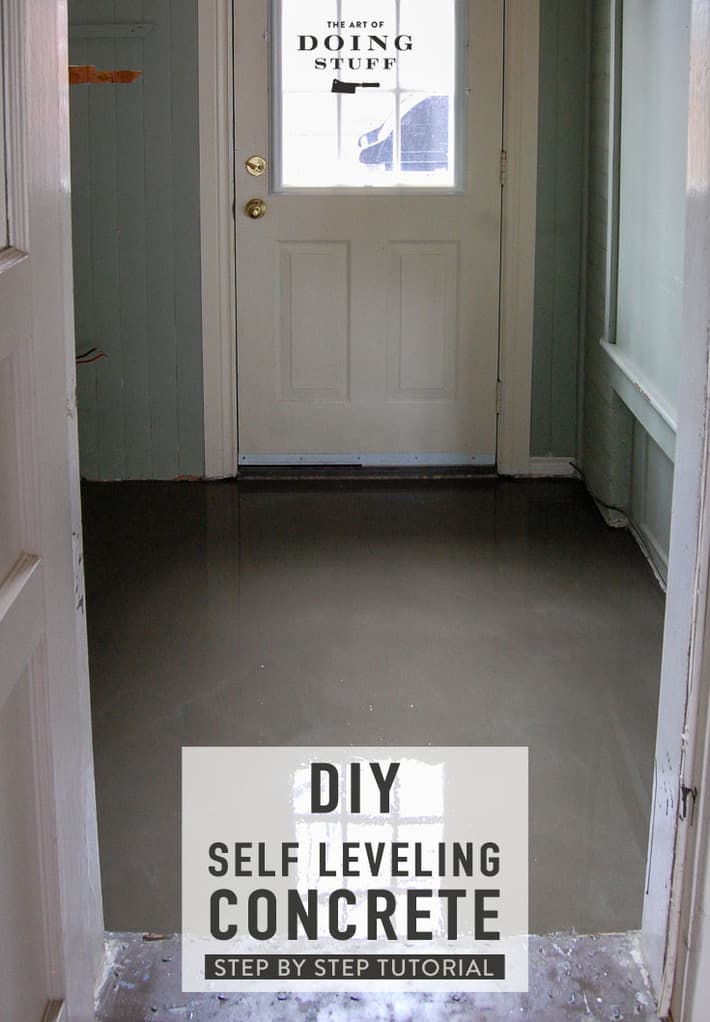

The mudroom went perfectly well. It couldn't have gone better so I continued onto the kitchen where things were a bit tricker.

Tips for Larger Rooms

A bigger room means you have to pour the buckets of concrete, run back to the mixer and mix up another batch (which needs to be mixed a longgg time), run through the house with a 50 pound bucket of cement and pour it where you left off. And repeat.

- Larger rooms are easier to do if there are 2 people working. One mixing the cement and one pouring it.

- Use a stiff squeegee on a long broom handle for pushing and pulling the compound into place.

NOTE: Wet concrete is caustic and can burn.

YOU HAVE TO WASH YOUR FEET IMMEDIATELY AFTER YOU WALK THROUGH IT. Do so after every time you walk through it. Also don't walk through wet cement if you have open cuts.

- If you find bits of unmixed lumps of cement. Just mush them with your fingertips.

- You may need to do a second coat if the first coat didn't cover. You could still see the heated floor mats I installed after the first coat, so I did a second.

It may look uneven, but it's just an optical illusion. The photo on the right is a levelled floor that is perfectly smooth.

- After leveling if you have any issue with dips and bumps you can correct them with a bit of Durabond 90. (fill, let dry, then sand)

Would you ever want to pour self leveling concrete?

To level an uneven concrete floor.

If you have a wonky basement floor that's uneven you can use self leveling concrete to smooth everything out and get it nice and flat. It's even handy if your concrete floors are just filthy. A thin layer of this will give you nice, clean concrete floors.

To prep a floor for laying down tile or to encase radiant floor heating.

The reason I poured it in my kitchen, bathroom and mudroom was so I could put down radiant floor heating. There's no basement or crawlspace at the back of my house which makes the floors pretty darn cold in the middle of a Canadian winter.

How much does a 50 lb bag of self leveler cover?

How much the cement will cover depends on how thick you will need it to be. This mudroom is around 30 square feet and one 50 pound bag of cement just barely covered it at about ¼" thickness.

Quick drying self leveling cement

Starts to set up in 5 minutes. This is only used when you have a small area to do and are an experienced concrete finisher.

Regular drying self leveling cement

It starts to set up within 15 minutes. This gives the amateur user much more working time. Those extra 10 minutes make a huge difference when you aren't exactly sure of what the hell you're doing.

The Self Leveling Cement *Quick Guide*

A quick guide to pouring self leveling cement. Refer to post for in depth instructions.

Materials

- Regular Self leveling cement*

- Leveling Primer**

- a cement mixing paddle

- a 5 gallon bucket

- a trowel

- filler (Durabond 90).

Tools

- Strong drill (I rented an industrial one)

Instructions

Scrape up any loose debris or tiles from the floor.

Build dams to stop the cement from going anywhere you don't want it to go.*

Fill any holes and/or cracks in the floor that the liquid cement could run down. I use Durabond 90.

Vacuum to get the surface perfectly clean.

Add water to your bucket (amount will be stated on your bag of cement)

Add ⅓ of the bag of cement into the water.

Mix with the drill and cement paddle, continually adding the rest of the bag of cement until everything is incorporated and then mix for the length of time given on the bag.

Here we go. Pour the self leveling cement into the desired area. Push and pull it into place with a trowel. It does self level but needs some help getting around.

And now you wait for it to cure. You can walk on it within 24 hours and place heavy objects back in 3 days.

Notes

*It may also be called self leveling concrete, self leveling floor resurfacer or self leveling underlayment. Either way make sure you get REGULAR self levelling cement. Quick Dry lets you walk on it within 6 hours, but you have a much shorter working time, and for an amateur it's better to have as much working time with the product as possible.

**Primer is needed when you're pouring concrete onto a porous surface like another concrete floor. It isn't needed when pouring onto old tile.

**It's very liquidy so make sure you don't skip this step or you'll have cement running under your dishwasher or down your stairs or into other rooms! I used thin wood, heavy cardboard and duct tape to make dams.

Self levellers can be poured to an inch deep.

If for some reason your cement isn't level, didn't turn out right or wasn't poured quite deep enough, you can re-pour more cement as long as you do it before the initial cement cures. Don't exceed the total recommended depth of 1".

OTHER TUTORIALS REFERENCED IN THIS POST

p.s. I'm out of chips.

→Follow me on Instagram where I often make a fool of myself←

You are such a bad-ass mofo! I don't know many guys who would've tackled this project. Can't wait to see it all done up pretty!

Good job Karen. I love that product. It can fix anything!!

I have actually tackled a few jobs like this one and have felt wonderful after having done so. There is nothing more rewarding than accomplishing something you feared, but also accomplishing something that no one thought you were capable of. The feeling is one of perfect fulfillment. Well, maybe not as good as...well you know what I am talking about. But it is a great feeling, nonetheless.

Thanks for sharing your joy with us. Susan

Wow! Very impressive! This is going to be a kick arse warn floor!

Another factor is weather and humidity. Self leveling compounds are very wet and as it dries the moisture becomes vapor. If your windows aren't open or your heavy duty fan going at high speed, and if the weather is very humid, it's gonna be very unpleasant. Mold. Eww.

That self-leveling cement... you think I can make some planters, using a 5 gallon bucket and some old margarine tubs with that stuff? I love those cement planters... don't want to pay the money and definitely want to be able to brag that I "made them myself." Will that stuff work for that project?

Have you ever heard of hypertufa, Marti? It's a mixture of cement, peat moss and perlite. The finished product looks like concrete when you use the kind of mold you describe, but the result doesn't weigh as much.

No, I actually haven't heard of that, Cussot, so much thanks. Is it waterproof, as well? I'm sure I can do the research, now that you've steered me that direction. :)

Well thanks very much Karen. I was feeling pretty chuffed with myself making some slipcovers for my outdoor chairs. Now after reading this....I may need to go and overdose on S&V chips. Awesome job-very impressed!

I am so excited to see the vinyl flooring, I really wanted this in our new house.

Also Karen could a person possible finish self leveling concrete to make a cool industrial modern floor? I asked my hubby about this option a while ago and he said it was prone to cracking easily.

Ali - I'm not sure about cracking but it is difficult to get a nice finish on it. You have bubbles and speckles and tiny raised bumps to deal with if you don't pour it perfectly. Depends on how industrial looking you want the floor to be. ;)~ karen!

You rock, as usual. Someone should write a graphic novel about you! But then it would be non-fiction, because it's true. Ann

Thank you for posting this tutorian and sharing your experience with this cement. I've always been kind of spooked by the idea of putting down cement myself....it's just so permanent..lol.

Maude

Thank you, Karen, I've saved this page to my bathroom flooring notebook, along with the others in this series. Thank you, also, for the link to figure out how much it might cost for the electricity. For our bathroom, where we live, it would be about $50 a year to have the flooring on 20 hours a day through the months we'd need it, so it looks like this is a real possibility for redoing our bath floor!

My husband has just caught me reading this post and is now slightly perturbed that I may be thinking of self-levelling something.

I suppose he is right to be worried - we didn't have chickens until I discovered 'The Art of Doing Stuff'!

Thank goodness the place I'm looking at doing this is small. It looks great so far, and the self-leveling stuff looks like something you managed well in large quantity and I could manage in small quantity. Do you need the self-leveling concrete only if you're using "soft" tiles, or do you also need it if you are using ceramic tiles? I'm as certain that you've mentioned the answer to this already, as I am that I've forgotten it already. I can't wait to see the finished project. You truly are an inspiration to us all.

Hi Susan - The self levelling concrete is only needed if you're laying heated floors and will be laying VCT tiles over top. If you're laying heated floors with ceramic over top you would not use self levelling cement, but regular tile cement like you normally would with laying ceramic tile. ~ karen!

Well, Karen. Awestruck. Just awestruck! In fact, we have a kitchen floor that is strangely not level--where the eating area meets the workspace, the linoleum sort of slopes sharply down, oh, 2 inches or so. Sort of a sunken kitchen. But not in a good way! Your stunning post is making me think that maybe, just maybe....this is a project that is fixable and not something that means we'll have to live here for the rest of our lives because no one else in the world would ever buy a house with this odd affliction... (why did we??) You have made me realize we might be able to move somewhere else, sometime in this lifetime! I thank you for that, Karen.

And btw, did you just leave the mudroom floor as cement, sans tile? Kind of cool, if so. Thanks for your awesomeness.

I must say...I'm impressed with you, and impressed with the project. Great job, and I will be listing it in my notebook full of projects I never want to tackle!

I never doubted you..not for one minute..In my next life..I want to come back as you..

Thanks for this. We've been putting off doing a bathroom because it is going to need leveling. You are just the thing to encourage us to move ahead on it. I love everything that you do.

A project like this just "blows my mind" Karen. This is something I could only do inside a nightmare. I'd be afraid of permanently bonding the friidge or the stove to the floor and having to hire simeone to jackhammer them out. Or, the back door getting stuck and never being able to get it to open again. Or, standing in one place a little too long in my bare feet and getting stuck. You really are amazing! And yet, you make it all look so easy.

Karen, is there a reason why you didn't remove the baseboards? I'm assuming they act as a dam. But does it not make it difficult (impossible?) to replace the baseboards later?

On a different note... You remind me of my mom. She was always fearless at tackling any sort of task. Build a 12 foot tall retaining wall out of railroad ties? Done. Train a horse wild off the range -- best horse ever btw? Done. Raise a zoo of animals for her "tribe of monkeys." Done. She's a great role model, as are you.

Hi Tina - It's hard to see in the pictures, but for the most part, the baseboards are raised up from where I removed the flooring beneath them. So the cement actually went *under* the baseboards. The are a couple of small spots (only 5" runs or so where baseboards go along solid cabints) where that isn't the case, but if the time ever comes to replace the baseboards, they'll be easy enough to remove with a crowbar and a whack of a hammer. ~ karen!

So when you ran out did you star over again or pick up where you left off? Ive just self leveled and have a low point still. I was wondering if I should get an extra bag or two and just self level the low point or do the entire floor all over again? Also, if you let the self level go under the baseboard wont that make it hard for the tile to fit underneath it when you finish? Just want some advice, I covered my baseboard with a tape dam but now feel like that edge tile that goes under the baseboard will be uneven. HELP!

Hi Torri. You should be able to just add more self levelling cement on top but you need to do it within a day or so of pouring the other cement in order for it to stick. otherwise the new layer will just sit on top of the first layer and over time it will crack and break. If you have trouble with not having enough room under your baseboard it's not a huge problem, you can just carefully chip away the cement. (it's hard for me to give advice not seeing exactly what you're talking about) Hope that helps! ~ karen!

Yep.....HE-RO!!!

You are my heroine. I respect you as a role model *and* i'm addicted to your website :o)

Sorry about your mouth. I've had a simliar injuriy after eating Captain Crunch.

LOL, I know what you mean about Captain Crunch. OUCH!